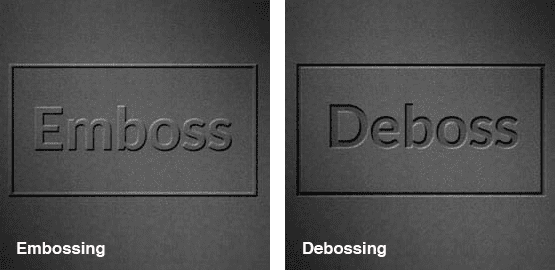

Embossing and Debossing

Embossing is a technique that is used to create a raised shape or image on selected areas of paper, providing a tactile and visual contrast against the flatness of the rest of the sheet. The embossed area becomes three-dimensional, which makes it an excellent choice for adding texture and depth to your printed materials.

This method is typically used where a high-end, bespoke look is desired, such as for wedding stationery, letterheads, folders, certificates, packaging, and other printed materials. Embossing can help to create a premium and sophisticated feel to your printed materials, which can be especially useful for creating a memorable impression for your business or brand.

How is embossing applied

Embossing can also be applied to cup sleeves to create a unique and eye-catching design. To achieve this, the paper sleeve is placed between two metal dies – one with a raised pattern and the other with a recessed version of the same pattern. Heat and pressure are applied to the dies, which squeezes the paper fibers and creates the embossed area on the sleeve. This method adds texture and depth to the design, making it stand out from other plain cup sleeves.

Types of embossing

Blind Embossing

Blind embossing refers to creating a raised area on paper without the use of ink or foil, resulting in an unprinted but noticeable contrast. This method can handle small details and is often used for a subtle yet impactful effect on various printed materials such as cup sleeves, business cards, invitations, and more.

Registered Embossing

Embossing in conjunction with print, foil or spot UV varnish (or a combination of more than one of these). By using a second embossed area, even more contrast can be achieved.

Combination Embossing

An image is printed, foiled or applied in spot UV and the embossing is aligned to the image so that the printed image is stamped out. This method is particularly suited to text and simple images.

Debossing

Debossing is the same process as embossing, except that the metal dies are transposed so that the area is stamped into the paper, creating a recessed or dented area. This technique can be used for cup sleeves to create a tactile effect. The debossed area can be left unprinted, providing a subtle contrast to the surrounding printed elements, or it can be filled with ink or foiling for more visual impact.

Things to consider before you start

Artwork

For the best results in embossing, vector files are recommended since they can be resized without losing quality. It’s important to keep the design simple, with limited shading and preferably one color, to ensure the embossing stands out and is not lost in the print. This is particularly important when using combination embossing.

Choosing the embossed area

Using embossing or debossing sparingly can help to maximize the impact of the design. However, the use of this technique ultimately depends on the specific item in question. For instance, an all-over embossed or debossed pattern can work well for invitations or business cards. In some cases, a registered or combination embossed area can be used to create contrast against the background pattern. Ultimately, the design should be tailored to suit the purpose and aesthetic of the item being produced.

Choosing the pattern and Paper weight

For cup sleeves, it’s important to consider the thickness and sturdiness of the paper, as well as the depth of the embossing. Using a heavy paper weight is recommended for deep embossing to avoid weakening the paper. It’s important to keep in mind that cup sleeves have limited surface area, so the embossing should be simple and not too deep to avoid tearing the paper. Using a shallow or medium depth embossing with a heavier paper weight can provide a clear and detailed image on the cup sleeve.

Consider the reverse

The embossing or debossing process will move the paper to the other side of the sheet so there will inevitably be a raised or recessed area on the other side of the sheet.

If you have any further questions about embossing or debossing then call us on 023 8087 8037 or email us.